We are leading Hydraulic Power Press Machines Manufacturers in India, Dealers, Suppliers, Exporters of Hydraulic Power Press Machinesin India. We provide C Type Hydraulic Power Press Machine Manufacturers, Hydraulic Power Press Cutting Machine Manufacturers, Hydraulic Power Press Machine Manufacturers, Manual Hydraulic Power Press Machine Manufacturers, Mini Hydraulic Power Press Machine Manufacturers, Small hydraulic power press machine Manufacturers and Pillar Type Hydraulic Power Press Machine Manufacturers in India

Hi-Tech Machines is a leading name among Hydraulic Power Press Machines Manufacturers, Dealers, Suppliers, Exporters in India. We hold especially in excellence, and we provide several General Type Hydraulic Power Press Machines, Manual Hydraulic Power Press Machines, Mini Hydraulic Power Press Machines, and Pillar-Type Hydraulic Power Press Machines in India, built with care and high durability. Each machine is designed and developed as per international standards, making sure that it performs well in every application. More than that, products focus productivity on unmatched reliability and efficiency. We try to satisfy customers better by offering solutions customized to their operational needs. From catering for ahigh-speed production-capable hydraulic power press cutting machine to small hydraulic power press machines in India, we have everything you require with our amazing power andefficiency.

The Manual Hydraulic Power Press Machine is as simple as operation comes, yet it remains quite reliable. The Pillar Type Hydraulic Power Press Machine offers a unique upturn of heavy capability and strength in operation. Machines really become depended on by customers for strong, high-performance machines with the guarantee of providing the best after-sales support. Our product should be designed by international standards so that holding them would bring benefits in terms of long-term value and lower operational costs. We have kept above all customer relations, so always attempting to provide the best solutions in hydraulic press for business use in India.

Some of the top Hydraulic Power press machine manufacturers in India presents an extensive range of high-grade Machines that are flexible enough to be applied in all types of Machines as follows:

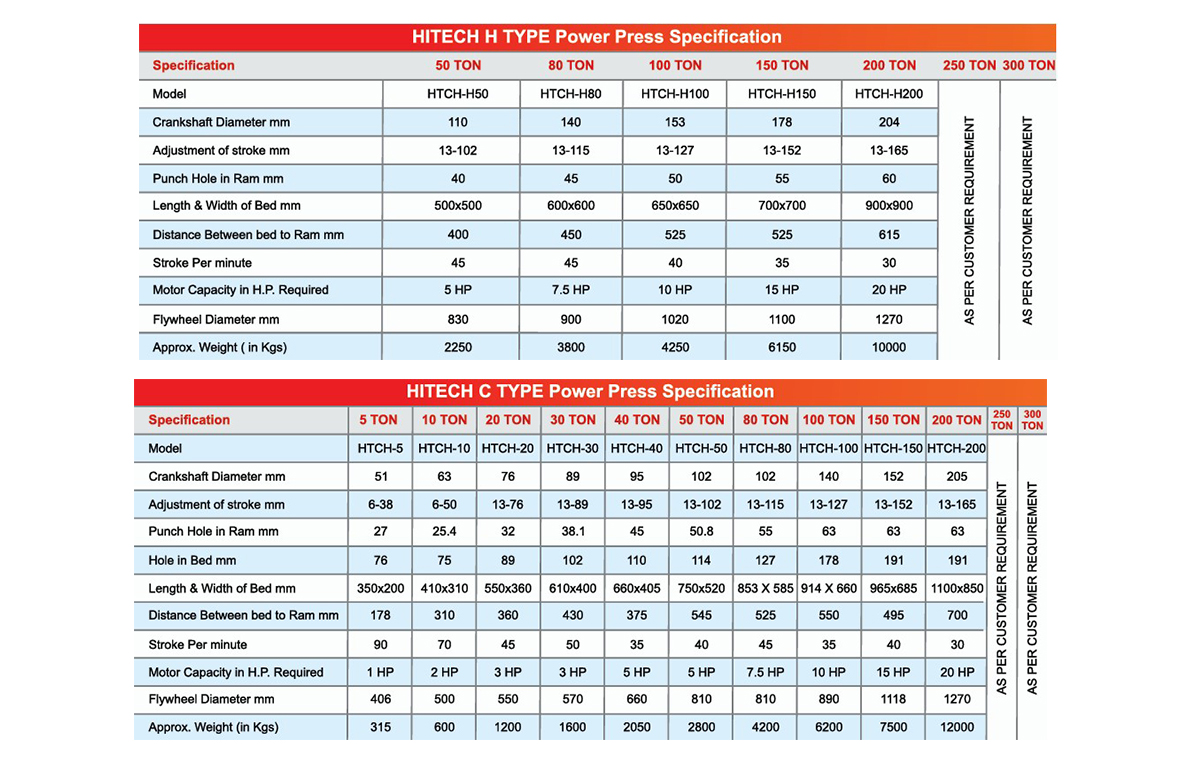

We have added below a technical sheet of our Hydraulic Power press machine that provides more technical information such as:

| Parameter | Specification |

|---|---|

| Model | HP100, HP200, and HP300 |

| Press Capacity (T) | 100, 200, and 300 |

| Stroke Length (mm) | 100 - 500 |

| Max. Ram Force | Up to 300 Tons |

| Working Pressure | 100-250 Bar |

| Motor Power | 7.5 kW to 30 kW |

| Drive Type | Hydraulic or Electric Motor Driven |

| Speed (No Load) | 10-20 SPM |

| Stroke Depth | Adjustable from 10 mm to 100 mm |

| Ram Adjustment Mechanism | Manual, Pneumatic, or Servo-Controlled |

| Control System | PLC with HMI |

| Weight (Kg) | 1500 kg - 6000 kg |

We are engaged for a range of Hydraulic Power Press Machine manufacturers, dealers, suppliers in India, offering all possible types of hydraulic power press machines manufactured according to the specifications, with the finest combinations of advanced technologies and different features such as:

As Hydraulic Power press machine dealers and suppliers in India, our Machines are highly demanded for multiple types of applications and used for improving performance, such as:

Hi-Tech Machines are the best names in Indian markets as manufacturers, dealers, suppliers, exporters of hydraulic power press machines. These machines are manufactured to perform precise tearing operations fittingly and effectively among various industries. Our Machines have been specially designed and manufactured, with a high emphasis on customer satisfaction, reliability, and excellent after-sales support. We are your partner for all hydraulic power presses as they increase productivity and operational efficiency.

Provides foundational support, enabling tilting and clamping for inclined presses.

Reciprocates within guideways, determining stroke length and power. Adjustable for specific requirements, with the bottom end carrying a punch for workpiece processing.

Positioned at the driving shaft's edge, connected through a clutch. Stores energy during idle periods, ensuring a consistent ram speed when engaging with the work.

Connects and disconnects the driving shaft from the flywheel, crucial for initiating or stopping ram movement.

Halts the driving shaft immediately after disconnection from the flywheel, ensuring precise control over the machine's operation.