Hi-Tech Machines is one of the best Hydraulic Press Brake Machine Manufacturers, dealer, supplier, wholesaler, trader, exporter in Pune. We provide the highest quality hydraulic press brake machine in India that are designed to work efficiently and accurately to meet your production needs. Our machines are easy to use, reliable, and cost-effective.

Hydraulic Press Brake Manufacturers in India or Hydraulic Press Brake Machine Manufacturers in India |Hydraulic Press Brake Manufacturers|Hydraulic Press Brake in India| Hydraulic Press Brake Dealers in India|Hydraulic Press Brake Suppliers in India|Hydraulic Press Brake Traders in India|Hydraulic Press Brake Wholesalers in India

Hi-Tech Machines is an eminent Hydraulic Press Brake Manufacturers, Dealer, Supplier, Exporters in India that offers an extensive range of high-performance Hydraulic Press Brakes in India that have been robust enough to fulfill the demanding needs of various industries. All hydraulic press brakes keep in mind precision engineering reliability and adequacy, which make them the best source to work on all kinds of metal works including bending and formingsheet metals. Whether sheet metal is thin or thick, it has always provided a perfect solution for obtaining results that are accurate and consistent.

Metal fabrication has no limits for this machine because it can work with steel; it can work with stainless steel and even aluminum. All hydraulic systems, present in these machines, give a greater pressure for bending thereby ensuring smooth and accurate bends at very high productions. Apart from this feature: adjustable bending speeds and shapes, a very user-friendly mode of operation, and an integrated back gauging system ensure perfect alignment for each bend. The press brake's precision is radically improved by such attributes.

Hydraulic Press Brakes set the bar for maximizing productivity while minimizing errors and material wastage. An operator can easily set bending angles, lengths, and so on in the equipment, ensuring great repeatability and precision while putting in minimal effort. The machines are ideal for applications in the automotive, aerospace, construction, and general metal working industries, where precision and efficiency characterize successful production. Offering reliable, high-quality machines built to last for more than a few years, being Hydraulic Press Brakes in India, we also include full after-sales support which involves installation, training, and maintenance. This ensures that the Hydraulic Press Brake will have the best possible performance for many years, all backed by the setting of the highest standard.

These hydraulic press brake dealers are amongst the top in India, and offer a vast array of high-quality brakes flexible enough for application across all kinds of brakes, as follows:

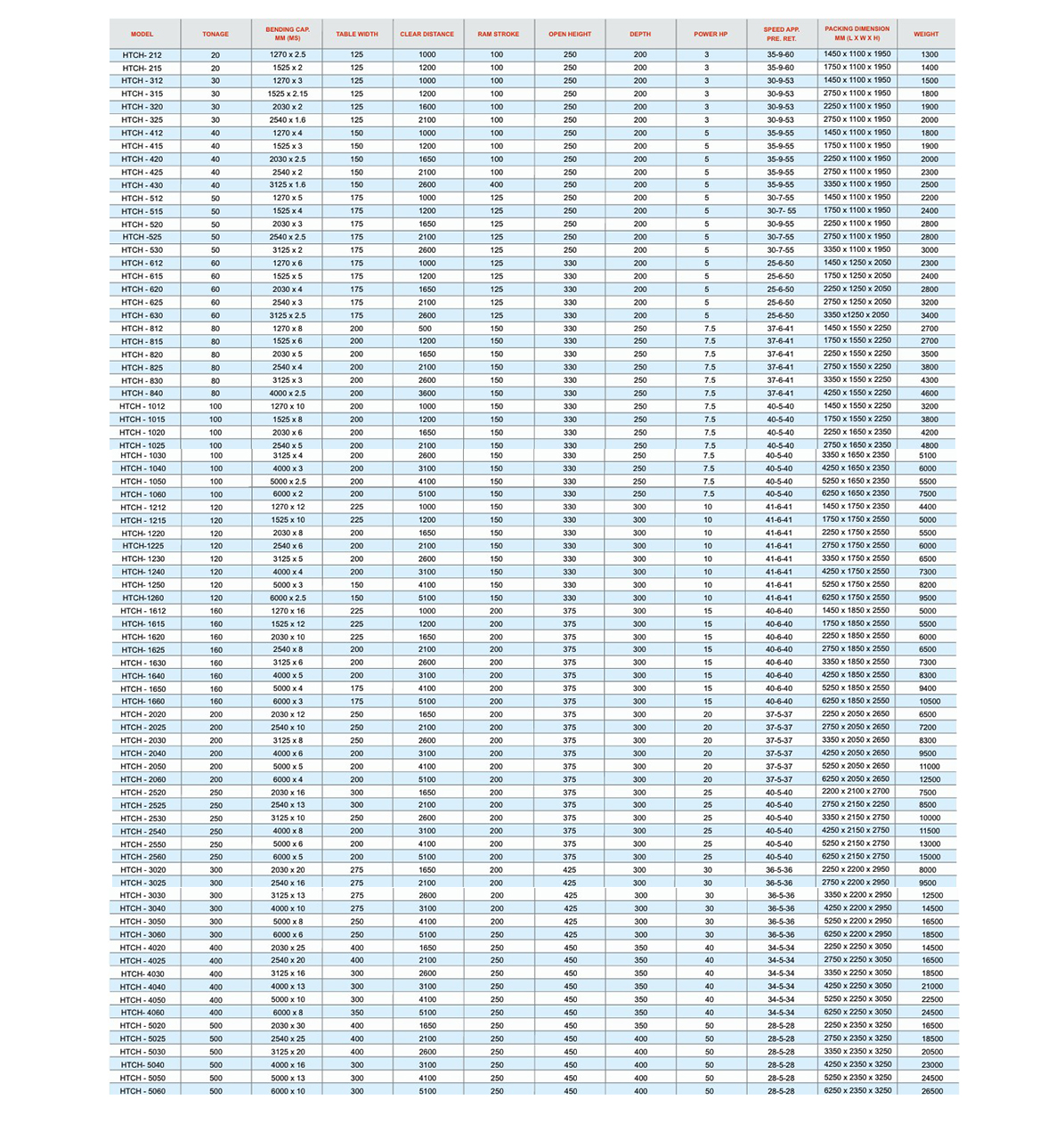

We incorporated below the technical sheet regarding our Hydraulic Press Brake, which contains further technical information, such as:

| Parameter | Specification |

|---|---|

| Machine Type | Hydraulic Press Brake |

| Bending Capacity | 30 tons to 2000 tons |

| Bending Length | 1000 mm to 8000 mm |

| Bending Accuracy | ± 0.1 mm to ± 0.5 mm |

| Max Bending Angle | 0° to 180° |

| Control System | CNC, NC, or Manual Control |

| Axis Control | 2 to 6 Axis Control |

| Ram Stroke Length | 100 mm to 500 mm |

| Throat Depth | 250 mm to 500 mm |

| Max Open Height | 300 mm to 1000 mm |

| Work Table Height | 800 mm to 1200 mm |

| Main Motor Power | 7.5 kW to 75 kW |

| Oil Tank Capacity | 150 to 800 liters |

| Max Pressure | 2000 to 3200 psi |

| Stroke Speed | 5 to 25 mm/sec |

| Working Speed | 5 to 15 mm/sec |

| Weight | 3000 kg to 30,000 kg |

| Power Supply | 380V/50Hz |

As an available best Hydraulic Press Brake Manufacturers in India, all categories of Hydraulic Press Brake with advanced technologies and have been absolutely justified with volumes of benefits such as:

As Hydraulic Press Brake dealers and suppliers in India, our Brakes are highly demanded for multiple types of applications and used for improving performance, such as:

Hi-Tech Machines-Machinery well known for the best in the hydraulic press brake dealers, suppliers, wholesalers, and traders in India. With machines that speak of high quality, we provide advanced, reliable, and efficient solutions for various bending applications. Our esteemed team ensures that every customer who walks through our doors finds the precision and life they want in hydraulic press brakes. Hence we are the most sought-out company by industries across India.

The frame provides the structural support and rigidity to the press brake. It ensures stability during the bending operation and supports the other components such as the hydraulic system, ram, and bed.

The bed, also called the lower beam or bedplate, provides support for the bottom of the workpiece during bending. It is usually equipped with a die set that helps shape the metal into the desired form. The bed may also have adjustable features to accommodate different die sets and workpiece sizes.

The hydraulic system is responsible for generating the force required to bend the metal. It typically consists of hydraulic cylinders, hydraulic pumps, valves, hoses, and a reservoir. The hydraulic pump pressurizes hydraulic fluid, which is then transferred to the hydraulic cylinders to actuate the bending process.

The ram, also known as the upper beam or slide, is the moving part of the press brake that applies force to the workpiece. It is controlled by the hydraulic system and moves vertically to perform the bending operation.

The die set consists of an upper and lower die that shapes the metal during bending. The upper die is mounted on the ram, while the lower die is fixed to the bed. Die sets come in various shapes and sizes to accommodate different bending requirements, such as V-dies, U-dies, and acute angle dies.

The back gauge is a positioning device located behind the bed that helps accurately position the workpiece for bending. It can be manually adjusted or controlled electronically, depending on the machine's capabilities. The back gauge ensures consistent bending accuracy and repeatability.

Modern hydraulic press brake machines are often equipped with a control system, which may include a CNC (Computer Numerical Control) interface. The control system allows operators to input bending parameters such as bend angle, bend length, and material thickness. CNC controlled press brakes offer precise control over the bending process and can automate repetitive tasks.