Top Mechanical Shearing Machine Manufactuers in India, Suppliers, Dealers, Exporters|Hi-Tech Machines. As leading Mechanical Shearing Machine Manufactuers from India, offering wide range of Mechanical Shearing Machine or Industrial Mechanical Shearing Machine in India. We also Mechanical Under Crank Shearing Machine Manufacturers, Mechanical Over Crank Shearing Machine Manufacturers in India by Hi-Tech Machines India. Request a Quote for best Mechanical Shearing Machines from India.

We are leading Mechanical Shearing Machine Manufactuers, Mechanical Shearing Machine Dealers, Mechanical Shearing Machine Suppliers, Exporters in India. We also offering Industrial mechanical shearing machine Manufacturers, Mechanical Under Crank Shearing Machine Manufacturers, Mechanical Over Crank Shearing Machine Manufacturers in India by Hi-Tech Machines India. Find here best quality Industrial mechanical shearing machines from India.

Hi-Tech Machines is the most trusted name among Mechanical Shearing Machines Manufacturers, Dealers, Suppliers, Exporters in India. We focus on providing the latest high-tech shearing solutions for every kind of industry in India. Our end-to-end Mechanical Shearing Machines in India range includes highly advanced models with precision and efficiency. We take pride in offering top-notch machinery and boast of having those that cater to demanding applications, such as Industrial Mechanical Shearing Machines, Mechanical Under Crank Shearing Machines, and Mechanical Over Crank Shearing Machines.

We have Mechanical Shearing Machines to match all industries from sheet metal fabrication to heavy weight cutting. If Mechanical Under Crank Shearing Machine you would like to use for straight and precise cuts or a Mechanical Over Crank Shearing Machine for more strength and efficiency in cutting thicker materials, but then we have now come up with these fine machines. These machines are designed with rugged mechanical construction and advanced hydraulic systems for excellent performance and high cutting capability that guarantees smooth, highly precise shearing operations with minimal waste of materials.

The Industrial Mechanical Shearing Machines in India is designed to work with extreme reliability even under heavy industrial workloads. With easy operable controls, angled cutting for adjustment, and hardened blades, these machines give consistent and accurate cuts every time. Our Mechanical Shearing Machines are made for heavy applications, with long service life without precision and quality loss.

Some of the top Mechanical Shearing Machine Manufacturers in India present an extensive range of high-grade Machines that are flexible enough to be applied in all types of Machines as follows:

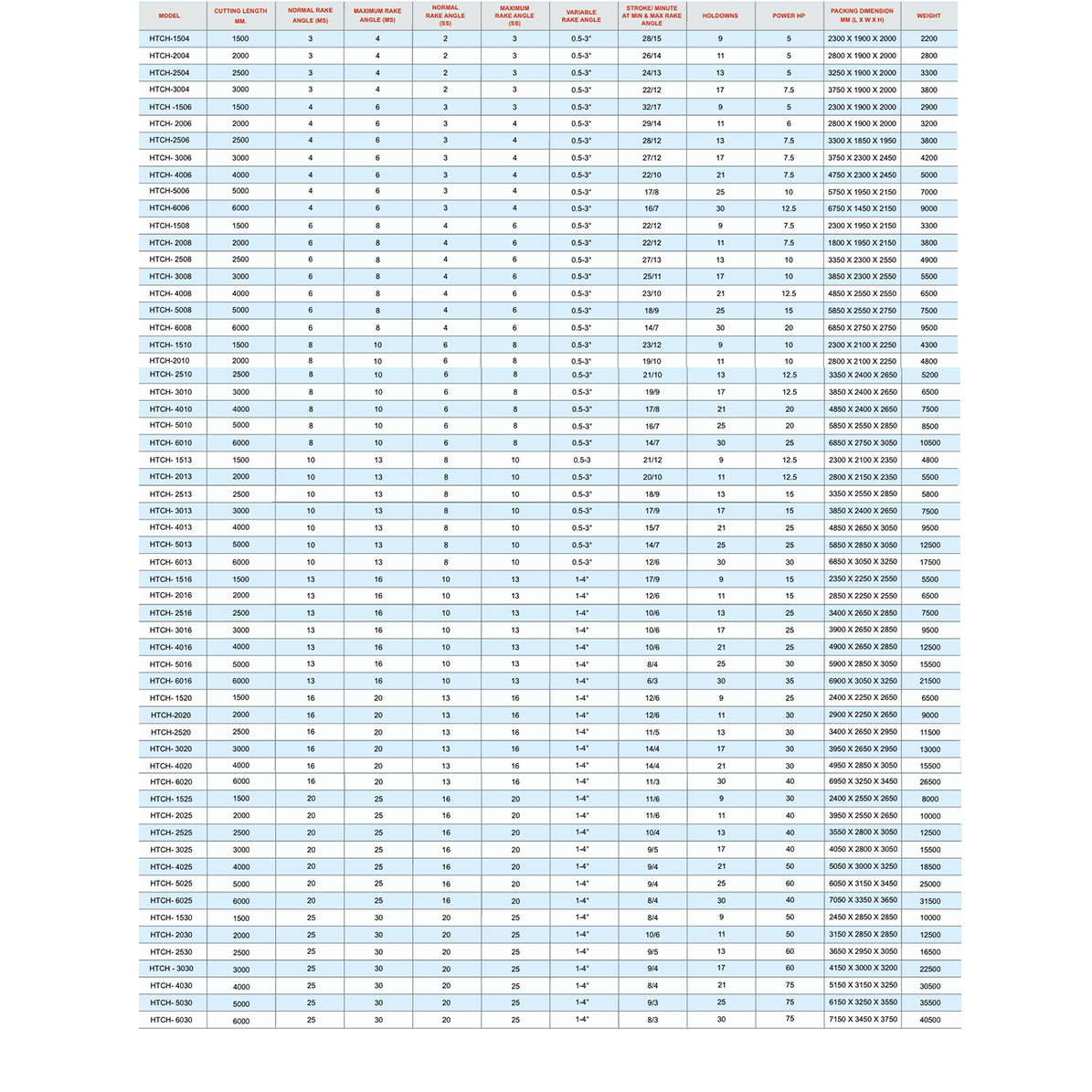

We have added below a technical sheet of our Mechanical Shearing Machine that provides more technical information such as:

| Parameter | Specification |

|---|---|

| Machine Type | Mechanical Shearing Machine |

| Cutting Capacity | 1 mm to 40 mm |

| Cutting Length | 1300 mm to 6000 mm |

| Cutting Angle | 0° to 2° |

| Cutting Speed | 10 to 30 strokes/min |

| Shear Force | 30 to 1000 tons |

| Blade Material | High Carbon Steel, Tool Steel, or Tungsten Carbide |

| Blade Gap Adjustment | Manual or Automatic Adjustment |

| Frame Material | Welded Steel or Cast Iron |

| Maximum Clearance | 20 mm to 200 mm |

| Stroke Length | 10 mm to 150 mm |

| Stroke Speed | 10 to 20 mm/sec |

| Motor Power | 5.5 kW to 75 kW |

| Motor Type | AC Motor, 3-Phase |

| Weight | 2,000 kg to 25,000 kg |

| Noise Level | 75–85 dB |

| Power Supply | 380V/50Hz |

As one of the best Mechanical Shearing Machine Dealers and Suppliers in India, all types of Mechanical Shearing Machine are built with advanced technologies and give multiple benefits, such as:

As Mechanical Shearing Machine Dealers in India, our Machines are highly demanded for multiple types of applications and used for improving performance, such as:

In India, Hi-Tech Machines is an established name among Mechanical Shearing Machine Manufacturers, Dealers, Suppliers, Exporters. These shears were designed especially for industries such as metal fabrication, and construction. We are excellent partners on high-shearing solutions as their efficiency reflects productivity and assured durability because we have been always very particular about quality, reliability, and service.