Top Pneumatic Power Press Machine Manufacturers in India and Pneumatic Power Press Machine Suppliers, Pneumatic Power Press Machine Dealers, Pneumatic Power Press Machine Exporters in India. We offer Pneumatic Power Press Machine in India or Pneumatic Power Press in India.Get a Quote Now.

A Pneumatic Power Press Machine is an essential piece of industrial equipment used for shaping, cutting, and forming materials, typically metals, by applying high pressure. These Pneumatic Power Press Machine in India are widely utilized in manufacturing processes such as stamping, punching, bending, and shearing. Power presses operate with precision and efficiency, enabling mass production of uniform components.

Hi-Tech Machines-Pneumatic Power Press Machine Manufacturers|Pneumatic Power Press Machine Dealers|Pneumatic Power Press Machine Suppliers in India. We are leading Pneumatic Power Press Machine Manufacturers in India and Pneumatic Power Press Machine Dealers in India.Pneumatic Power Presses are widely used in various industries for their efficiency, precision, and reliability. As a leading manufacturers and suppliers of Pneumatic Power Press Machine in India, we provide high-quality machines that cater to diverse industrial needs. Our Pneumatic Power Press Machine are designed to deliver smooth operation, durability, and customized solutions. With years of expertise and a strong presence in the industry, we have established ourselves as a trusted partner for businesses seeking reliable Pneumatic Power Press Machine in India.

We are leading Pneumatic Power Press Machine Manufacturers in India, Dealers, Suppliers, Exporters of Pneumatic Power Press Machine in India. We are offering best quality Pneumatic Power Press Machine in India by Hi-Tech Machines. Find the best Pneumatic Power Press Machine Manufacturers in India. We are Pneumatic Power Press in India, Pneumatic Power Press Machine in India, Pneumatic Power Press Machine Manufacturers, Pneumatic Power Press Machine Manufacturers in India, Pneumatic Power Press Machine Dealers in India, Pneumatic Power Press Machine Suppliers in India

Hi-Tech Machines provide Pneumatic Power Press Machine Manufacturers, Dealers, Suppliers, Exporters in India. As a brand synonymous with high-quality Pneumatic Power Press Machines in India, we make products for various industrial applications. We are well-known for our excellence and specialize in cutting-edge Pneumatic Power Press solutions that promise precision, efficiency, and durability in all applications. Designed for consistent performance in a wide range of operations, such as punching, stamping, and metal forming, these machines are built to last. We, as one of the best Pneumatic Power Press in India, do ensure delivery of goods meeting all quality levels and reliability standards required.

We offer a Pneumatic Power Press with a complete line of machines powered by compressed air forces, thus are very economical and able to produce forces. Such machines can be most relevant to industries that are looking for cost-effective, versatile solutions to medium to high runs of output.The Pneumatic Power Press provides a quiet operation with low maintenance and ever-increasing productivity. Whether it's a stamping job requiring a Pneumatic Power Press Machine or a more sophisticated sheet metal operation, we're here to offer you machines tailored to your needs.

The most renowned Pneumatic Power Press manufacturers in India have smartly gathered a wide range of high-quality presses to skillfully cater to the demands of all kinds of Pneumatic Power Press systems. Such presses include the following:

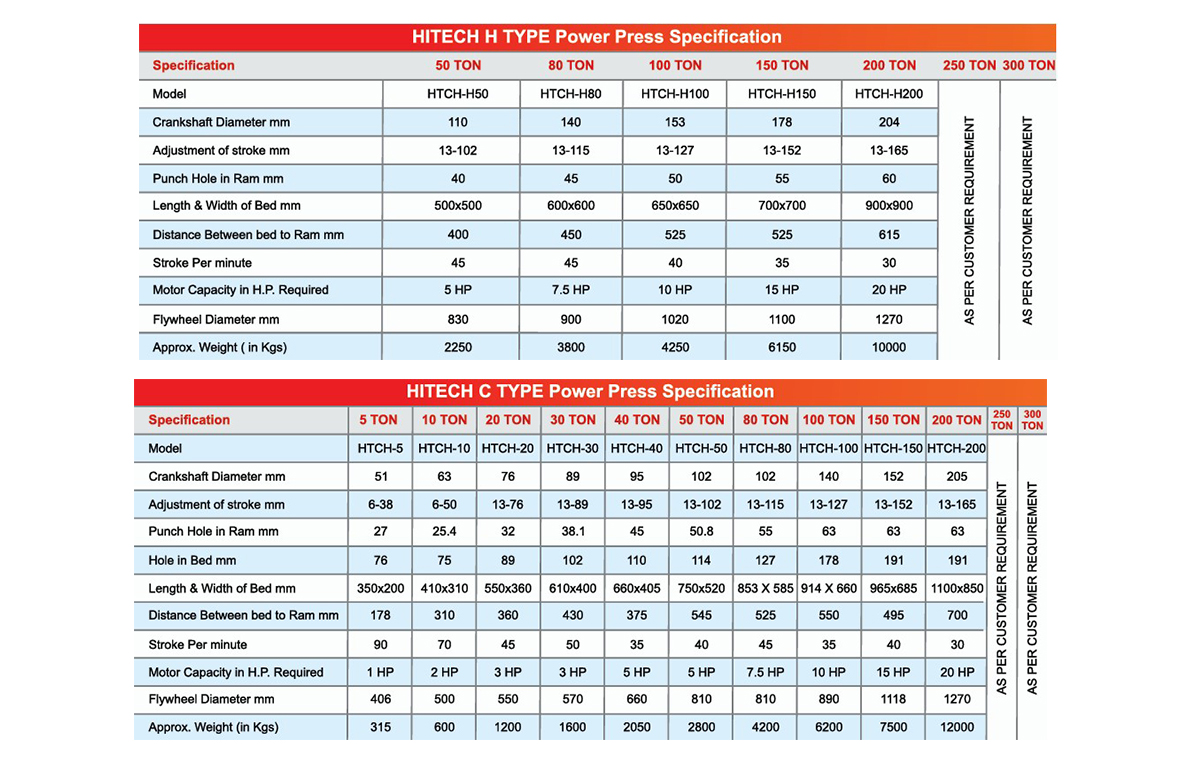

We have added below a technical sheet of our Pneumatic Power Press that provides more technical information such as:

| Parameter | Specification |

|---|---|

| Model | PP10, PP20, PP30 |

| Press Capacity (T) | 10, 20, and 30 |

| Stroke Length | 50 mm - 200 mm |

| Max. Ram Force | Up to 30 Tons |

| Ram Stroke Adjustment | Pneumatic or Manual Adjustment |

| Working Pressure | 5-8 Bar |

| Motor Power | 2 kW to 10 kW |

| Weight (kg) | 1000 kg - 3500 kg |

As one of the best Pneumatic Power Press Manufacturers and Suppliers in India, all types of Pneumatic Power Press are built with advanced technologies and give multiple benefits, such as:

As Pneumatic Power Press Manufacturers in India, our Press are highly demanded multiple types of applications used for improving performance, such as:

Hi-Tech Machines is a well-known name in the industry as one of the Pneumatic Power Press Machine Manufacturers, Dealers, Suppliers, Exporters in India. We highly specialize in supplying pneumatic power press machines,enduring, high performance, and delivering results in every industry reliable and trusted. We are the finest associate for everything dealing with pneumatic presses fuel efficiency, precision, and productivity in your business with quality assurance, assurance of customer satisfaction, and all after-sales service.

Related Searches: Pneumatic Power Press in India, Pneumatic Power Press Machine in India, Pneumatic Power Press Machine Manufacturers, Pneumatic Power Press Machine Manufacturers in India, Pneumatic Power Press Machine Dealers in India, Pneumatic Power Press Machine Suppliers in India, Pneumatic Power Press Machine Traders in India, Pneumatic Power Press Wholesalers in India

Provides foundational support, enabling tilting and clamping for inclined presses.

Reciprocates within guideways, determining stroke length and power. Adjustable for specific requirements, with the bottom end carrying a punch for workpiece processing.

Positioned at the driving shaft's edge, connected through a clutch. Stores energy during idle periods, ensuring a consistent ram speed when engaging with the work.

Connects and disconnects the driving shaft from the flywheel, crucial for initiating or stopping ram movement.

Halts the driving shaft immediately after disconnection from the flywheel, ensuring precise control over the machine's operation.